AC Engine Project

Life for The Weller 2 Litre 6 Cylinder Engine

New Development For the AC Weller Engine Project

2009 Starts with major news for the AC Engine Project:

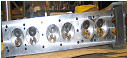

The new cylinder head soon to go into testing

Four Photos of the head being built can be seen to the left - click on them to enlarge for a better view.

The head is being fitted with the new design cam, rocker shaft and high lift rockers.

We have recently gained the approval from the VSCC for the AC Engine Project's Blocks, sumps and cylinder heads; a seal of approval to the authentic nature aims of the Project.

VSCC Approval Letters:

Block and Sump

Cylinder Head

Aluminium Cylinder Heads - VSCC approved

New heads will be available in the New Year in Aluminium; these have been approved by the VSCC & are made to official AC drawings.

The combustion chambers have been designed to achieve a compression ratio of 8.23 to 1 using a flat top piston level with liner top. - Notes:

Please note that the compression ratios on the Weller engine vary widely, the new head will be consistent on the compression ratio in standard form.

For competition or to gain higher compressions, then pistons with modified crowns are used to gain compressions 9:1 and above.

The porting has been re-designed so there are six independent induction ports of 1.375'' diameter blended to a 1.5'' inlet valve. A land will exist between the ports to ensure sealing of a new designed inlet manifold which will have an appropriately sized balance manifold.

Exhaust ports are to be made round blended from the 1.3'' diameter valve. One may therefore use existing exhaust manifolds but some blending is recommended.

Valve seats will be fitted as standard to suit unleaded fuel.

NOTE: The heads will suit both Pre & Post War Engines.

An additional important feature is that an independent oil feed will be sited on the rear exhaust side of the head which will feed directly into the oil passage below the rear camshaft pedestal which is of 3/8'' BSP female tapping to which a banjo metering valve may be fitted to regulate oil to the camshaft & rocker assembly.

This will obviate the need for oil to be fed from number four main bearing via a rather contorted rout! Oil may feed directly from the oil filter which is immediately below this point.

This will ensure all main bearings receive good oil flow & avoid oil starvation to the head. Good consistent well filtered oil flow is most important to ensure minimal engine wear (Oil Filters with 15 micron filtration are available with the pressure relief valve fitted correctly after filtration takes place see web site)

A secondary benefit is that the head will be approximately 15 kilo's lighter which does I understand improve overall car balance on Ace's, if you then have the benefit of the new Pre Engage Starter Motors a further reduction of 4 kilo's is available. It all helps!

A good deal of work has been carried out to gain knowledge of the working of the AC head. There are a lot of overlooked aspects on the head design that need care and attention to maintain the proper working of the engine. Regardless of the engine being used for pottering on the road on a sunny day, or tuned to race, issues arise which should be looked at:

Camshaft timing, lift & cam shape.

Rocker Shaft wear - this causes varying cam lift and therefore inconsistent breathing. Note the standard Rocker Shaft is too short to fully engage into the front rocker pedestal housing, this, has the consequence of Fretting damage to shaft & housing. It is recommended to fit modified longer shafts of the correct specification namely EN40B steel in 'T' condition which is ground & nitrided to give a surface hardness of over 800 VPN - See products page.

Rocker fingers - a new design is being produced to reduce roller inertia and consequent wear due to slippage.

Valve Springs - the standard AC springs are not ideal for the application, As such the double spring specification has problems and causes compromise. We have specified new springs that are designed to perform optimally at all engine speeds expected for the Weller engine and all states of tune. These new springs have a significantly higher resonant frequency to match engine speeds up to 6,000 RPM, in addition they will not bind up & therefore overstress the rocker which may be a significant cause of breakage on full deflection using the AC specification springs.

Value Guides and Stem seals - by using our new springs the added benefit is the option to used better valve guides and stem seals - stem seals not being an easy option with the AC designed double springs.

Sumps

Ace owners have to take the engine out to take the sump off, this means expense and risk of damaging their car. The new sump will make it possible to take the sump off with the engine still in the car - a big bonus. - Now Here

Crankshaft and Cams - Watch this space!

New Camshaft Bearing Studs

New studs that are designed for the new alumium head, but will fit the standard head; the thread length may need to be altered as the tread goes deeper into the aluminium head, but not a problem as easy to shorten.

The new cylinder head soon to go into testing

Four Photos of the head being built can be seen to the left - click on them to enlarge for a better view.

The head is being fitted with the new design cam, rocker shaft and high lift rockers.

We have recently gained the approval from the VSCC for the AC Engine Project's Blocks, sumps and cylinder heads; a seal of approval to the authentic nature aims of the Project.

VSCC Approval Letters:

Block and Sump

Cylinder Head

Aluminium Cylinder Heads - VSCC approved

New heads will be available in the New Year in Aluminium; these have been approved by the VSCC & are made to official AC drawings.

The combustion chambers have been designed to achieve a compression ratio of 8.23 to 1 using a flat top piston level with liner top. - Notes:

Please note that the compression ratios on the Weller engine vary widely, the new head will be consistent on the compression ratio in standard form.

For competition or to gain higher compressions, then pistons with modified crowns are used to gain compressions 9:1 and above.

The porting has been re-designed so there are six independent induction ports of 1.375'' diameter blended to a 1.5'' inlet valve. A land will exist between the ports to ensure sealing of a new designed inlet manifold which will have an appropriately sized balance manifold.

Exhaust ports are to be made round blended from the 1.3'' diameter valve. One may therefore use existing exhaust manifolds but some blending is recommended.

Valve seats will be fitted as standard to suit unleaded fuel.

NOTE: The heads will suit both Pre & Post War Engines.

An additional important feature is that an independent oil feed will be sited on the rear exhaust side of the head which will feed directly into the oil passage below the rear camshaft pedestal which is of 3/8'' BSP female tapping to which a banjo metering valve may be fitted to regulate oil to the camshaft & rocker assembly.

This will obviate the need for oil to be fed from number four main bearing via a rather contorted rout! Oil may feed directly from the oil filter which is immediately below this point.

This will ensure all main bearings receive good oil flow & avoid oil starvation to the head. Good consistent well filtered oil flow is most important to ensure minimal engine wear (Oil Filters with 15 micron filtration are available with the pressure relief valve fitted correctly after filtration takes place see web site)

A secondary benefit is that the head will be approximately 15 kilo's lighter which does I understand improve overall car balance on Ace's, if you then have the benefit of the new Pre Engage Starter Motors a further reduction of 4 kilo's is available. It all helps!

(Keep watching this web site for progress)

Further Head developments available for new and existing engines:A good deal of work has been carried out to gain knowledge of the working of the AC head. There are a lot of overlooked aspects on the head design that need care and attention to maintain the proper working of the engine. Regardless of the engine being used for pottering on the road on a sunny day, or tuned to race, issues arise which should be looked at:

Camshaft timing, lift & cam shape.

Rocker Shaft wear - this causes varying cam lift and therefore inconsistent breathing. Note the standard Rocker Shaft is too short to fully engage into the front rocker pedestal housing, this, has the consequence of Fretting damage to shaft & housing. It is recommended to fit modified longer shafts of the correct specification namely EN40B steel in 'T' condition which is ground & nitrided to give a surface hardness of over 800 VPN - See products page.

Rocker fingers - a new design is being produced to reduce roller inertia and consequent wear due to slippage.

Valve Springs - the standard AC springs are not ideal for the application, As such the double spring specification has problems and causes compromise. We have specified new springs that are designed to perform optimally at all engine speeds expected for the Weller engine and all states of tune. These new springs have a significantly higher resonant frequency to match engine speeds up to 6,000 RPM, in addition they will not bind up & therefore overstress the rocker which may be a significant cause of breakage on full deflection using the AC specification springs.

Value Guides and Stem seals - by using our new springs the added benefit is the option to used better valve guides and stem seals - stem seals not being an easy option with the AC designed double springs.

Sumps

Ace owners have to take the engine out to take the sump off, this means expense and risk of damaging their car. The new sump will make it possible to take the sump off with the engine still in the car - a big bonus. - Now Here

Crankshaft and Cams - Watch this space!

New Camshaft Bearing Studs

New studs that are designed for the new alumium head, but will fit the standard head; the thread length may need to be altered as the tread goes deeper into the aluminium head, but not a problem as easy to shorten.