AC Engine Project

Life for The Weller 2 Litre 6 Cylinder Engine

Products

PVT

Engine Blocks

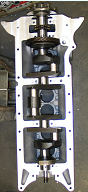

Engine Blocks

Casting Patterns & Tooling made to AC Drawings & existing PVT Blocks, Significant improvements have been made to strengthen the block, allow for larger Crankshaft Main bearing journals on all five bearings. The webs have been thickened to the full width of the casting to enable wider pitch main bearing studs to be fitted which allows larger main bearings to be used, the main bearing caps may also be double bolted each side of the bearing.

Improved cooling can be facilitated with the addition of an external feed pipe to the side of the block which has two water port pads cast into the block side. Front & rear crankshaft oil seals may be accommodated as the ends of the block may be counter bored. The front water entry pipe to the block is moved up by one inch to allow for a modern Crankshaft Damper to be fitted. Main bearing Oil feed is provided on the centre two webs which offer increased oil supply to the main bearings.

AC Crankshafts or New One piece Crankshafts machined from Billet may be accommodated as it fully conforms to the AC design requirement.

Blocks have VSCC approval as replacements to existing engines for use in Vintage & Post Vintage competitive events; in addition the blocks are approved to carry the AC logo.

Availability - Blocks are supplied fully machined with the exception of the main bearing housings & seal locations, Machining of these may be carried out as required together with the sump as a separate service, and in some cases honing of the main bearing housings is desirable which can be arranged.

Improved cooling can be facilitated with the addition of an external feed pipe to the side of the block which has two water port pads cast into the block side. Front & rear crankshaft oil seals may be accommodated as the ends of the block may be counter bored. The front water entry pipe to the block is moved up by one inch to allow for a modern Crankshaft Damper to be fitted. Main bearing Oil feed is provided on the centre two webs which offer increased oil supply to the main bearings.

AC Crankshafts or New One piece Crankshafts machined from Billet may be accommodated as it fully conforms to the AC design requirement.

Blocks have VSCC approval as replacements to existing engines for use in Vintage & Post Vintage competitive events; in addition the blocks are approved to carry the AC logo.

Availability - Blocks are supplied fully machined with the exception of the main bearing housings & seal locations, Machining of these may be carried out as required together with the sump as a separate service, and in some cases honing of the main bearing housings is desirable which can be arranged.

These blocks have the same benefits in design modifications but with the side front mounting feet & water cooling as standard through the side of the block & bosses for the water pump. The additional optional feature on both blocks is the addition of a side water feed pad to improve cooling & flow to the Numbers five & six liners.

Availability- to order as above

Availability- to order as above

Post War

Engine Blocks

Engine Blocks

Notes

Both Blocks will accommodate any AC crankshaft & new crankshafts having main journals up to 55 mm diameter, larger journal size than 55mm is not possible due To the constraint of the Camshaft drive sprocket, this journal size is however, Thought to be more than adequate for the engine. If you wish to retain your Existing AC Crankshaft which has Oil Flinger then an additional machining operation is required to accommodate this.

Side walls, lower flange & the front mounting feet are increased in thickness for additional

Strength which will also offer significantly extended life of the block.

It is important to understand what crankshafts, sumps are to be used & that these are available at the beginning of the project, if one requires one of the new design Crankshafts allowance must be made for these to be manufactured prior to starting the machining of the blocks.

Both Blocks will accommodate any AC crankshaft & new crankshafts having main journals up to 55 mm diameter, larger journal size than 55mm is not possible due To the constraint of the Camshaft drive sprocket, this journal size is however, Thought to be more than adequate for the engine. If you wish to retain your Existing AC Crankshaft which has Oil Flinger then an additional machining operation is required to accommodate this.

Side walls, lower flange & the front mounting feet are increased in thickness for additional

Strength which will also offer significantly extended life of the block.

It is important to understand what crankshafts, sumps are to be used & that these are available at the beginning of the project, if one requires one of the new design Crankshafts allowance must be made for these to be manufactured prior to starting the machining of the blocks.

PVT Engine Sumps

Designed with stronger walls & webs together with the facility to have front & rear crankshaft seals fitted, These are styled on the PVT design allowing the up rated Oil Pumps to be fitted together with a central oil pick up to ensure continuity of oil supply.

The integral Oil Filter housing & Pressure Relief Valve are not incorporated in favour of a separate Spin off Filter Head which incorporates the Pressure Relief valve. This Filter /Pressure relief housing is bolted to the side of the sump in place of the existing design allowing relief oil to pass directly to the sump through the flange.

The Sump design will fit both PVT & Post War Engines but the Starter motor position is as the PVT sump lower down which will require post war engines to have a PVT Bell housing.

As the sump is of a narrow design it may make it possible for ACE & ACECA owners to remove the sump with the engine in situ.

Additional facilities are that a central oil pick up is fitted & internal baffles may be added to ensure no loss of oil when braking or cornering.

The additional facility of that the oil pump housing being deeper allows for a larger volume oil pump to be fitted which is in production. The oil passage is also increased to match the new pump design.

Availability- Tooling is completed & some small modifications in progress so will be available to order.

The integral Oil Filter housing & Pressure Relief Valve are not incorporated in favour of a separate Spin off Filter Head which incorporates the Pressure Relief valve. This Filter /Pressure relief housing is bolted to the side of the sump in place of the existing design allowing relief oil to pass directly to the sump through the flange.

The Sump design will fit both PVT & Post War Engines but the Starter motor position is as the PVT sump lower down which will require post war engines to have a PVT Bell housing.

As the sump is of a narrow design it may make it possible for ACE & ACECA owners to remove the sump with the engine in situ.

Additional facilities are that a central oil pick up is fitted & internal baffles may be added to ensure no loss of oil when braking or cornering.

The additional facility of that the oil pump housing being deeper allows for a larger volume oil pump to be fitted which is in production. The oil passage is also increased to match the new pump design.

Availability- Tooling is completed & some small modifications in progress so will be available to order.

Oil Filter/ Pressure Relief

As described above allows for both filtering of the oil through a 15-micron full flow filter spin on/off canister & the relief of excess oil pressure from the oil pump to be directed back to the sump; this through the flange, in the case of fitting to a new PVT sumps. Where the unit is to be fitted to existing Engines or other applications a separate relief oil outlet fitting is provided.

The size of the filter canister is specified to have minimal pressure loss. This filter will fit any engine as a remote filter. It should also be noted that the pressure relief valve is after the filter so that no pressure drop occurs & full set pressure is delivered to the engine, a spare tapping is fitted to allow a direct oil feed to the new Aluminium cylinder head design & for the fitting of a pressure gauge.

Availability in Stock

The size of the filter canister is specified to have minimal pressure loss. This filter will fit any engine as a remote filter. It should also be noted that the pressure relief valve is after the filter so that no pressure drop occurs & full set pressure is delivered to the engine, a spare tapping is fitted to allow a direct oil feed to the new Aluminium cylinder head design & for the fitting of a pressure gauge.

Availability in Stock

New water pumps have new design (sealed for life) shaft, water seal & bearings, together with a new water impeller & pulley. Both outlet Flange & Hose fitting types can be accommodated.

A repair service is available for existing water pumps if that is required.

Availability in Stock

A repair service is available for existing water pumps if that is required.

Availability in Stock

PVT Water Pumps

Post War Water Pumps

A reconditioning service, fitting new bearings & seals, it is assumed that the old pump is in a repairable condition however.

Note a modification of the pump is in progress to fit a new bearing, seal & impeller system which will overcome the persistent sealing & bearing problems. I expect this to be available soon.

Note a modification of the pump is in progress to fit a new bearing, seal & impeller system which will overcome the persistent sealing & bearing problems. I expect this to be available soon.

New Crankshafts

AC Project Crankshaft for New Blocks

A completely new crankshafts design is now available which has up rated bearing journals being 55mm on all main journals together with 45mm big end journals, these are specifically designed to fit the new Cylinder Blocks, thin wall bearing shells are used which have a flanged number three centre main thrust bearing.

Oil sealing using modern lip seals to front & rear together with the provision of a front crankshaft damper to be fitted on both PVT & Post War designs.

New flywheels are required as the rear hub diameter is 3.125'' to allow for the fitting of the cross shaft gear, a light flywheel design is available to order.

For Existing UMB Engines

New single billet crankshaft designs are available which use thin wall shell bearings, the key issue is the selection of suitable shell bearings which can be fitted in the existing main bearing housings. Due to the shrinking after market availability careful selection is required & it is advisable to order spare bearing sets, generally larger journals are possible.

It is generally necessary to fit a new flywheel as the hub diameter is made to allow for the cross shaft bronze gear to be fitted.

A design lead time must be allowed for to ensure the design suits the customer's requirements.

Availability - Made to order & on a manufacturing lead time of 10-12 weeks.

A completely new crankshafts design is now available which has up rated bearing journals being 55mm on all main journals together with 45mm big end journals, these are specifically designed to fit the new Cylinder Blocks, thin wall bearing shells are used which have a flanged number three centre main thrust bearing.

Oil sealing using modern lip seals to front & rear together with the provision of a front crankshaft damper to be fitted on both PVT & Post War designs.

New flywheels are required as the rear hub diameter is 3.125'' to allow for the fitting of the cross shaft gear, a light flywheel design is available to order.

For Existing UMB Engines

New single billet crankshaft designs are available which use thin wall shell bearings, the key issue is the selection of suitable shell bearings which can be fitted in the existing main bearing housings. Due to the shrinking after market availability careful selection is required & it is advisable to order spare bearing sets, generally larger journals are possible.

It is generally necessary to fit a new flywheel as the hub diameter is made to allow for the cross shaft bronze gear to be fitted.

A design lead time must be allowed for to ensure the design suits the customer's requirements.

Availability - Made to order & on a manufacturing lead time of 10-12 weeks.

Con Rods

Con Rods of the 'I' & 'H' Cross Section are available to order; these are designed in conjunction with the new crankshaft design, in the case of the AC Project Crankshaft design these have 45mm diameter big end journals.

Con rods may also be supplied for other crankshafts with thin walled shell bearings & if for use on original AC Crankshafts the rod width must be made to suit the actual journal width to reduce too much end float!

Availability - Made to order & on 6-8 week lead time normally

Con rods may also be supplied for other crankshafts with thin walled shell bearings & if for use on original AC Crankshafts the rod width must be made to suit the actual journal width to reduce too much end float!

Availability - Made to order & on 6-8 week lead time normally

Crankshaft Harmonic Tortional dampers

Viscous damper designs have been selected for use on the new AC Project Design Crankshafts, these are available to order but can only be used on the new PVT Blocks which have adequate clearance below the water inlet, or may be used on Post War engines.

Some modifications will be required when fitting to an existing crankshaft.

A new light weight type is available shortly which has a lower inertia.

I am happy to discuss requirements.

Some modifications will be required when fitting to an existing crankshaft.

A new light weight type is available shortly which has a lower inertia.

I am happy to discuss requirements.

Crankshaft Flywheels

These are designed to be significantly lighter with lower inertia which is approximately half the weight of the existing AC Flywheel! These suit the new One Piece Crankshaft design.

Note with the new solid billet crankshaft design we are able to adopt the current industry practice of supporting the gearbox input shaft by a female bushing fitted to the Crankshaft; this facilitates clutch alignment with modern alignment tools.

Availability -To Order

Note with the new solid billet crankshaft design we are able to adopt the current industry practice of supporting the gearbox input shaft by a female bushing fitted to the Crankshaft; this facilitates clutch alignment with modern alignment tools.

Availability -To Order

Camshafts

New AC Engine Project Design

A completely new design of camshaft is now available in both Fast Road & Mild Competition form, these together with a new Hi Ratio Rocker design offer significantly higher valve lift & may be used on existing engines as well as the new Aluminium cylinder heads becoming available.

Part of the new design is to also have a torsionally stiffer lighter camshaft with lower inertia effects; these are shortly available as sets & will require modification of the valve system to suit the new rocker design which has a special adjustment foot.

It should be noted that these Camshafts will not work with the existing AC Rocker design.

Availability - in stock shortly.

Fast Road Camshafts

Fast Road Camshafts to suit best road performance & optimize the torque available in the AC engine. These are designed to not only optimize performance of the engine but be quieter & use a marginally smaller setting gap.

Availability - In stock

Mild Competition Camshaft

Mild Competition Camshafts are designed to suit general track requirements & obtain a sensible balance of the torque available in the AC engine & higher RPM.These are not generally considered suitable for road use but may be acceptable for those people who drive there cars to the track rather than transporting them.

Availability - In stock

A completely new design of camshaft is now available in both Fast Road & Mild Competition form, these together with a new Hi Ratio Rocker design offer significantly higher valve lift & may be used on existing engines as well as the new Aluminium cylinder heads becoming available.

Part of the new design is to also have a torsionally stiffer lighter camshaft with lower inertia effects; these are shortly available as sets & will require modification of the valve system to suit the new rocker design which has a special adjustment foot.

It should be noted that these Camshafts will not work with the existing AC Rocker design.

Availability - in stock shortly.

Fast Road Camshafts

Fast Road Camshafts to suit best road performance & optimize the torque available in the AC engine. These are designed to not only optimize performance of the engine but be quieter & use a marginally smaller setting gap.

Availability - In stock

Mild Competition Camshaft

Mild Competition Camshafts are designed to suit general track requirements & obtain a sensible balance of the torque available in the AC engine & higher RPM.These are not generally considered suitable for road use but may be acceptable for those people who drive there cars to the track rather than transporting them.

Availability - In stock

Adjustable Camshaft Duplex Chain Sprockets

Used in conjunction with the Camshaft Timing Procedure described in the FAQ's, this will assist in setting the cam timing to the exact requirements to suit the camshaft. This is an essential procedure to obtain optimum performance is possible whichever engine tune you have.

It should be noted that most camshaft sprockets will be worn as no spares have traditionally been available; sometimes it is thought that only the chain wears & replace only the chain without consideration for the sprocket.

Availability- now in stock More Information - Click Here

It should be noted that most camshaft sprockets will be worn as no spares have traditionally been available; sometimes it is thought that only the chain wears & replace only the chain without consideration for the sprocket.

Availability- now in stock More Information - Click Here

Starter Motors

Pre Engaged Gear Reduction Starter motors are in development, these will afford quicker starting with less current drain from battery, they will be approximately half the weight of the existing starter, these will fit all PVT & Post War Engines.

These are approved by VSCC.

Availability - Now Available

These are approved by VSCC.

Availability - Now Available

Alternator Conversion

Using 55amp alternator is in development with a working sample available for test, there is a significant output improvement over dynamos & is approximately half the weight of a dynamo.

These are however at present not acceptable to the VSCC but are an essential to improve lighting in the winter months & for night driving.

Consideration is being given for a look alike dynamo/alternator to be manufactured.

Availability - Available following tests

These are however at present not acceptable to the VSCC but are an essential to improve lighting in the winter months & for night driving.

Consideration is being given for a look alike dynamo/alternator to be manufactured.

Availability - Available following tests

Recondition Exchange Service available suitable specialists are available with sources given on the links part of the web site, an electronic type is available which has 15 pre set advance curves, however these may not be acceptable for historic events!

Availability Reconditioned exchange distributors can be available.

Availability Reconditioned exchange distributors can be available.

Distributors

New Gears, Bronze gear fitted to the Crankshaft & Steel cross Shaft gears made to original drawings available in stock, the Bronze gear is bored to suit standard crankshafts also bored for new crankshaft Register & bolting centres.

Availability in Stock

Note these are made to the correct gear form to match the original parts which has taken more time to complete the project, they are drilled to fit original AC crankshaft together with my new designed replacement crankshafts.

Availability in Stock

Note these are made to the correct gear form to match the original parts which has taken more time to complete the project, they are drilled to fit original AC crankshaft together with my new designed replacement crankshafts.

Cross Shaft Gear Set

Cross Shaft Shroud

Castings are ready for machining for new cross shaft gear shrouds; these tend to get damaged on fitting & are important to protect the gears.

Cross Shaft Bronze bearing Sets

These are in stock & will be fitted to new engine blocks as required.

Valve Rockers

New AC Project Development new rockers fitted with Needle Rollers in place of the solid original design, advantages expected to reduce roller friction on pin & lower inertia therefore reduce any skidding on cam face.

These are designed to suit the new camshaft design & have a higher ratio to facilitate increased valve movement, in addition to the needle roller follower a new swivel adjustment foot is fitted which offers an increased bearing surface to the valve stem top; this lowers the load intensity & self aligns.

It should be noted that the new Camshaft & Rocker design requires specific length valve stems & is designed around industry standard available valves, springs & collets etc, these have been selected to ensure efficient operation & none binding of the spring. Additionally more spring rates are available for engine development.

Availability - Shortly

These are designed to suit the new camshaft design & have a higher ratio to facilitate increased valve movement, in addition to the needle roller follower a new swivel adjustment foot is fitted which offers an increased bearing surface to the valve stem top; this lowers the load intensity & self aligns.

It should be noted that the new Camshaft & Rocker design requires specific length valve stems & is designed around industry standard available valves, springs & collets etc, these have been selected to ensure efficient operation & none binding of the spring. Additionally more spring rates are available for engine development.

Availability - Shortly

Rocker Shaft Upgrade

Rocker Shafts are now available in stock, modifications have been made to the length to enable greater engagement into the front & rear pedestals to increase the contact surface area & so reduce load intensity. This change is designed to reduce the high levels of fretting particularly at the front pedestal, a new oil feed drilling has been added to the front to supply oil to the camshaft bearings.

These modifications will better ensure uniform valve opening & more stability of the valve clearance settings; this should also offer a considerable increase in shaft life.

In Detail: The material used for the shaft is EN40B which is Plasma Nitrided after grinding, this surface is said to offer significant reduction of fretting wear & is a good bearing surface. The shaft length at the front pedestal is such that it enables greater depth of engagement into the pedestal. By means of a modification of the blind bored hole to bore through allowing the shaft to protrude marginally at the front. A 5/16 UNF tapping is added to allow the oil way end to be blanked off or a top hat cap added over the end.

Availability - Now

These modifications will better ensure uniform valve opening & more stability of the valve clearance settings; this should also offer a considerable increase in shaft life.

In Detail: The material used for the shaft is EN40B which is Plasma Nitrided after grinding, this surface is said to offer significant reduction of fretting wear & is a good bearing surface. The shaft length at the front pedestal is such that it enables greater depth of engagement into the pedestal. By means of a modification of the blind bored hole to bore through allowing the shaft to protrude marginally at the front. A 5/16 UNF tapping is added to allow the oil way end to be blanked off or a top hat cap added over the end.

Availability - Now

Head Studs with Roll- Formed threads

Sets of new studs which have rolled formed threads in S99 High tensile Steel; they are made to a significantly higher specification than the original studs from AC and are the best on the market.

A supply of nuts in EN24 is available together with a special hi load washer.

Availability - Now

A supply of nuts in EN24 is available together with a special hi load washer.

Availability - Now

Head Gaskets

New Gasket material has been on test for some months now, these gaskets are made from Tanged Graphite material bonded both sides of a Stainless Steel Mat, they are 2mm thick & are a direct alternative to the Copper/Asbestos type gaskets which are now only available on a small batch Hand made basis?

Tanged Graphite gaskets are very compliant & offer high temperature & pressure advantages. Some further development work is in hand to offer further improvements & consideration to alternates!

Availability In development.

Tanged Graphite gaskets are very compliant & offer high temperature & pressure advantages. Some further development work is in hand to offer further improvements & consideration to alternates!

Availability In development.

Liner Lower Figure of Eight Gaskets

These are available in 0.25 mm thick for latest specification 4'' Liners & 2mm for existing liners; some shoulder length adjustment may be required when refitting Old liners.

This is intended to simplify the fitting of liners particularly when fitting new specification liners.

New Liners are now available, these are 4 inches between shoulders & allow the potential to use an 'O' Ring seal instead of a figure of eight gasket, this does mean however that the top shoulder of the liners are flush with the block & does require some development of the head gaskets to accommodate this.

Availability further development being considered.

This is intended to simplify the fitting of liners particularly when fitting new specification liners.

New Liners are now available, these are 4 inches between shoulders & allow the potential to use an 'O' Ring seal instead of a figure of eight gasket, this does mean however that the top shoulder of the liners are flush with the block & does require some development of the head gaskets to accommodate this.

Availability further development being considered.

New Roll formed Camshaft Bearing Studs which are made from EN24T steel, these are basically intended for the new aluminium cylinder heads but can be available in sets for sale for standard heads.

Heavy duty washers are also available together with 5/16''BSF nuts.

Availability - Now

Heavy duty washers are also available together with 5/16''BSF nuts.

Availability - Now

Roll formed Camshaft Bearing Studs