AC Engine Project

Life for The Weller 2 Litre 6 Cylinder Engine

Current Development For the AC Weller Engine Project

These are the new conventional shape con rods to complement our new crankshaft design, these take modern thin wall shell bearings which have increased journal diameter, with careful design we have a journal diameter of 45mm with acceptable swing clearance, these are matched sets of equal weight, another important point is that with our new design liners we should avoid interference problems with the lower liners so avoiding major fettling in assembly.

Camshaft Bearing studs are of high strength steel with all threads roll formed, we have marginally increased the length to suit our new Rocker Covers

This is our special design crankshaft which is expected to reach & exceed 6000 RPM in use, the main journals are all 55mm diameter with the con rod journals 45mm diameter, this allows us to have a very strong section across the web areas which is improved with good fillet radii, two crankshaft types are available one for pre-war engines & the second for post war engines, both designs have the nose fitting for a crankshaft damper, lip seals are to fitted both ends & the flywheel is bolted using twelve bolts.

Precise drillings are required to ensure good oil flow as we have reduced to rotating weight of the crankshaft pins by boring through; these crankshafts are made from EN40B billet material & nitrided on all journals, special care is taken to ensure the duplex sprockets are to a tough condition.

Precise drillings are required to ensure good oil flow as we have reduced to rotating weight of the crankshaft pins by boring through; these crankshafts are made from EN40B billet material & nitrided on all journals, special care is taken to ensure the duplex sprockets are to a tough condition.

This is our lightweight Flywheel design made to suit or new design crankshafts, we have achieved an approximate 50% weight saving overall but more significant is the much lower inertia load.

A view showing the proximity of the head to block to piston, this piston being a very hi compression type, a rarely seen picture as we have sectioned a cylinder head in the process of designing the new head tooling.

This is the lightweight version of the crankshaft damper we recommend for use on our new crankshaft designs & are suitable for pre-war & post War engines we supply, this is a friction type damper both Viscous & 'Rattler' type dampers can be fitted dependent upon preference, we do however strongly recommend these be fitted.

The new engine blocks have been specifically modified to accept these dampers & in particular the Pre-war (cat's Paw) blocks, whilst they can be fitted to existing post war blocks it is not possible to use them on existing pre-war blocks or those supplied by our competitor!

You are probably fully aware of the measures AC took to overcome crankshaft resonance & its harmonics by the use of a split flywheel to raise the combined of the crankshaft/flywheel assembly in the early engines & then post war to use a bonded disc damper which was designed to be effective at the crankshaft resonant frequency, both of these measures had limited benefit & in the case of the bonded type tend to change frequency as the bonding & material degrades.

A key requirement is that the damper is a good push fit to the crankshaft to avoid fretting wear so our crankshafts are specifically designed to accept these special dampers.

The new engine blocks have been specifically modified to accept these dampers & in particular the Pre-war (cat's Paw) blocks, whilst they can be fitted to existing post war blocks it is not possible to use them on existing pre-war blocks or those supplied by our competitor!

You are probably fully aware of the measures AC took to overcome crankshaft resonance & its harmonics by the use of a split flywheel to raise the combined of the crankshaft/flywheel assembly in the early engines & then post war to use a bonded disc damper which was designed to be effective at the crankshaft resonant frequency, both of these measures had limited benefit & in the case of the bonded type tend to change frequency as the bonding & material degrades.

A key requirement is that the damper is a good push fit to the crankshaft to avoid fretting wear so our crankshafts are specifically designed to accept these special dampers.

Distributor drive gears are now available as replacements, whilst these do not wear to any great extent some have suffered from corrosion, basically these are needed mainly for new engines where no suitable used ones are available.

Cylinder Head Studs, made from high tensile 12/9 steel with roll formed threads, these are specially sized to enable a good fit to the engine blocks & are available in the 9.5'' length & 10.5'' length, fourteen are required in most engines four long & ten short, however some engines require fourteen short type.

Special Long nuts & high load washers are also available & can be supplied in sets.

Special Long nuts & high load washers are also available & can be supplied in sets.

New AC Engine Camshaft Rocker, designed to suit our new high lift camshafts for both Fast Road & Mild Competition use, we are at present designing a new full competition camshaft which will have marginally more valve lift.

The Rockers are equipped with a fully loaded 19mm diameter high strength needle roller together with an 'Elephants Foot' valve adjuster, the geometry is designed such that maximum contact is maintained to the valve stem so as the rocker rotates it moves from one side to the other uniformly.

These are of strong design Investment Cast Steel heat treated to give good impact strength.

The Rockers are equipped with a fully loaded 19mm diameter high strength needle roller together with an 'Elephants Foot' valve adjuster, the geometry is designed such that maximum contact is maintained to the valve stem so as the rocker rotates it moves from one side to the other uniformly.

These are of strong design Investment Cast Steel heat treated to give good impact strength.

New AC Engine Project Cylinder Liners, these are specially made to standard size, bored & finish honed, the liners are four inches between flanges so that only a thin figure of eight casket is needed to fit the liners to correct height above the cylinder block top, they are made so that an 'O' ring seal may be fitted to seal the liner to block landing also.

Other changes are that the lower skirt is half of an inch shorter to afford more con rod swing clearance, the flange surfaces are flat without the previous groove AC machined into the surface which gave some sealing problems, and we believe these work well with new & old blocks.

Pistons are also available to suit at a 9.5-1 compression ratio; other ratios can be supplied.

Other changes are that the lower skirt is half of an inch shorter to afford more con rod swing clearance, the flange surfaces are flat without the previous groove AC machined into the surface which gave some sealing problems, and we believe these work well with new & old blocks.

Pistons are also available to suit at a 9.5-1 compression ratio; other ratios can be supplied.

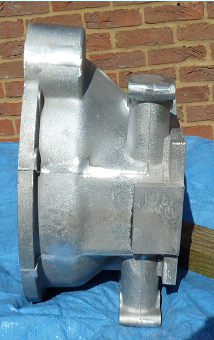

New AC Bell Housing for use on new Sumps & can be used on Pre War engines, this will allow the normal Moss Gearbox to be fitted also as it has a larger gearbox mounting flange which is also 1/4'' thicker it will accommodate post war gearboxes such as the T5 -five speed gearbox which has a marginally longer input shaft.

You will see from the pictures that the PVT tube mounting is accommodated as well as the post war pad used on the post war cars such as the 2-litre, Ace & Aceca, in addition it is possible to fit a secure mounting bracket for use with hydraulic clutch release slave cylinders which can be mounted either side of the housing.

Unfortunately these are not suitable for the normal post war sump due to the starter position being lower down which suits the new AC Engine Project narrow sump design.

We are trying to offer greater flexibility to owners who invest into the new engine/sump units but they are very suitable replacements for PVT bell housings which have damaged tube mounting bosses.

You will realise this is the first off casting which will be machined shortly.

You will see from the pictures that the PVT tube mounting is accommodated as well as the post war pad used on the post war cars such as the 2-litre, Ace & Aceca, in addition it is possible to fit a secure mounting bracket for use with hydraulic clutch release slave cylinders which can be mounted either side of the housing.

Unfortunately these are not suitable for the normal post war sump due to the starter position being lower down which suits the new AC Engine Project narrow sump design.

We are trying to offer greater flexibility to owners who invest into the new engine/sump units but they are very suitable replacements for PVT bell housings which have damaged tube mounting bosses.

You will realise this is the first off casting which will be machined shortly.

Our vernier Camshaft Sprocket allows the adjustment of the camshaft in relation to the crankshaft with greater accuracy there being a tooth & half movement as well as the ability to rotate the sprocket to a second set of holes for greater adjustment, this we feel is quite adequate for normal timing requirements. You will see that we have six special locking bolts which afford good retention without causing damage to the slots, the chain wheel we believe must be kept as strong as possible when one considers the loading on it so we do not have extended slots which are not necessary anyway, these can be retro fitted to any engine.

AC Cylinder Head Gasket

We have new modern design gaskets which you can see in the attached picture, it is a stainless steel mat with a the gasket material tanged onto both sides, the cylinder bores are fitted with a copper compression ring which has a brass support between the pairs of cylinders called a 'Dog Bone', both sides have a 0.002'' high silk screened bead on both sides where the seal contact the block edges & around the stud positions, the whole gasket is then conformal coated & cured.

We recommend the liner height is 0.005'' above the block edge & the liners are held firm at this dimension & that they cannot compress down more than 10% , this ensures that no significant movement takes place when the studs are being torque down to the recommended torque.

Other points to check is the flatness of the block & cylinder head & that no significant corrosion has occurred on the joint faces, particularly the aluminium block, care must be taken to ensure the head studs are in good condition, caution must be taken if you attempt to remove the studs if they are corroded in the block as to remove the broken stud is very difficult.

We have new modern design gaskets which you can see in the attached picture, it is a stainless steel mat with a the gasket material tanged onto both sides, the cylinder bores are fitted with a copper compression ring which has a brass support between the pairs of cylinders called a 'Dog Bone', both sides have a 0.002'' high silk screened bead on both sides where the seal contact the block edges & around the stud positions, the whole gasket is then conformal coated & cured.

We recommend the liner height is 0.005'' above the block edge & the liners are held firm at this dimension & that they cannot compress down more than 10% , this ensures that no significant movement takes place when the studs are being torque down to the recommended torque.

Other points to check is the flatness of the block & cylinder head & that no significant corrosion has occurred on the joint faces, particularly the aluminium block, care must be taken to ensure the head studs are in good condition, caution must be taken if you attempt to remove the studs if they are corroded in the block as to remove the broken stud is very difficult.

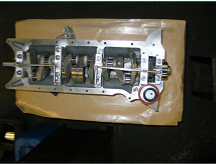

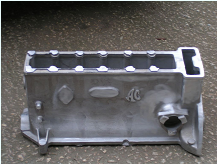

Pre War & Post War blocks we manufacture; in fact we are the only source for the post war engine blocks. All blocks are produced with marginally thicker walls & stronger front mounting feet, they also have the number two & three main bearing webs made full width so enabling wider main bearing caps to be fitted & double bolted to add strength & stiffness.

PVT blocks have the inlet water port lifted by one inch to allow a crankshaft damper to be fitted so overcoming a major vibration problem due to low resonance crankshaft assemblies.

You will see one picture showing our new crankshaft fitted in a PVT block with the oil manifold ready for final fitting; all blocks have a double oil entry one on each web two & three, this allows more potential oil flow to the crankshaft. We also leave the post war water port pads & water pump bosses on all blocks so offering some potential modifications of water flow & say the fitting of a timing indicator.

Lip seals can be fitted to the front and rear of the crankshaft, original AC crankshafts can be accommodated by adding the oil flinger slot. While the blocks will accept the original AC components we believe the best route is to have a new Block, Sump & crankshaft so we can offer a strong assembly, it offers a new strong basis for the engine & should give good service life.

PVT blocks have the inlet water port lifted by one inch to allow a crankshaft damper to be fitted so overcoming a major vibration problem due to low resonance crankshaft assemblies.

You will see one picture showing our new crankshaft fitted in a PVT block with the oil manifold ready for final fitting; all blocks have a double oil entry one on each web two & three, this allows more potential oil flow to the crankshaft. We also leave the post war water port pads & water pump bosses on all blocks so offering some potential modifications of water flow & say the fitting of a timing indicator.

Lip seals can be fitted to the front and rear of the crankshaft, original AC crankshafts can be accommodated by adding the oil flinger slot. While the blocks will accept the original AC components we believe the best route is to have a new Block, Sump & crankshaft so we can offer a strong assembly, it offers a new strong basis for the engine & should give good service life.