AC Engine Project

Life for The Weller 2 Litre 6 Cylinder Engine

Project Update Easter 2014

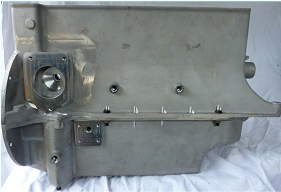

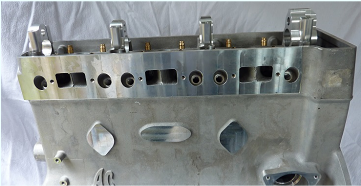

The AC Engine Project is now nearing maturity, we started the project as I had a need for a new PVT Engine Block for my 16/80 Competition 2-seater, and whilst Werner Oswald had produced some in the 1980's these were a copy of the original design which I felt required some strengthening and stiffening in key places also the provision of larger main bearing journals, it was therefore decided to have new tooling created with the improvements and future proofing I felt was needed. To ensure we were able to manufacture new blocks correctly it was necessary to obtain a complete set of available drawings from the then existing AC Car Company who unfortunately only had the Post War drawings as the pre war drawings were lost in a fire in1950's, AC agreed to allow me to purchase the drawings from them for an agreed sum and allow the use of the AC logo on the blocks.

Before serious investment into tooling I gained the approval of the VSCC on the new parts including any planned improvements this was given as were approvals of the various parts such as Aluminium Cylinder Heads etc.

As the project developed more key parts were covered to the extent that we are now able to reproduce complete PVT and Post War Engines to cover all periods in which AC Cars were made using the 'Weller Six Cylinder Single Overhead Camshaft Engine'.

Consideration was given to improving the potential of the engine within the scope of the original Weller design so we then set about the re-design and upgrading of most of the rotating parts incorporating the opportunity to allow significant performance improvements.

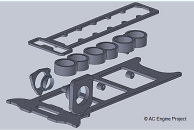

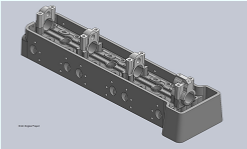

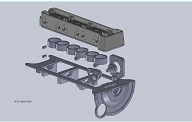

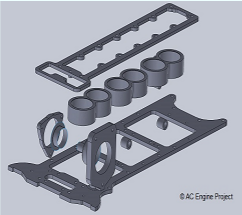

Later we will explain each part in some detail so the full scope of the changes can be understood and the approach we have taken, where needed experienced and qualified designers were engaged to carry out specific new designs on parts such as Crankshafts, Camshafts and Rocker systems to enable greater valve lift. A number of improvements were needed to the valve porting areas to eliminate areas of interrupted gas flow underneath the valve seats which was carried out when new mould coring was made.

Having now supplied several engines to owners in the UK, Europe and USA some of which had existing AC parts fitted such as Crankshafts etc it has become clear that whist this can and has been done with good results the potential of the engines has not been realised, in some cases these parts were varying and required significant changes to the blocks to enable the parts to be fitted! The time and costs involved in the supply assembly and testing of engines is quite considerable and it is often as costly to use old parts as the supply of new better designed parts which can afford much more reliability and longer engine life. We have therefore decided that we should focus our offering to the fully finished block, sumps and complementary parts for which our up rated crankshaft can be used using modern thin walled bearing shells. On this basis all new blocks are to this standard and will be available ex stock, we have a new crankshaft on the shelf for a PVT engine assembly so can offer a very predictable delivery.

Following this preamble we will itemise each major part we can supply and the reasoning behind the parts where significant improvements have been made, the fundamental behind all parts is as follows:-

To offer both Pre War and Post War Engine parts

Where essential major Castings have been strengthened.

Significant attention has been made to ensure increased and good oil flow, filtering and pressure control.

Water and Combustion Chamber Sealing has been improved with re-designed cylinder liners, sealing and modern design head gaskets.

The use of stronger/stiffer crankshaft designs has allowed the use of modern thin wall shell bearings which enables higher loads to be taken safely with higher RPM opportunity to gain higher power levels over a wider Rev range.

Parts have been made lighter where possible particularly the parts such as flywheels, starter motors and in particular Cylinder Heads by the use of Aluminium rather than Cast Iron.

We employ high quality specialist manufacturing companies to produce tooling, castings and carry out machining using the latest computer aided machinery, we use the highest grades of materials and latest processes in the manufacture of specialist parts. Assembly has been simplified so that minimal manual intervention is necessary to complete a satisfactory engine build, we have minimal use of gasket sealing as the machining quality is such that modern liquid sealants can be adopted.

Before serious investment into tooling I gained the approval of the VSCC on the new parts including any planned improvements this was given as were approvals of the various parts such as Aluminium Cylinder Heads etc.

As the project developed more key parts were covered to the extent that we are now able to reproduce complete PVT and Post War Engines to cover all periods in which AC Cars were made using the 'Weller Six Cylinder Single Overhead Camshaft Engine'.

Consideration was given to improving the potential of the engine within the scope of the original Weller design so we then set about the re-design and upgrading of most of the rotating parts incorporating the opportunity to allow significant performance improvements.

Later we will explain each part in some detail so the full scope of the changes can be understood and the approach we have taken, where needed experienced and qualified designers were engaged to carry out specific new designs on parts such as Crankshafts, Camshafts and Rocker systems to enable greater valve lift. A number of improvements were needed to the valve porting areas to eliminate areas of interrupted gas flow underneath the valve seats which was carried out when new mould coring was made.

Having now supplied several engines to owners in the UK, Europe and USA some of which had existing AC parts fitted such as Crankshafts etc it has become clear that whist this can and has been done with good results the potential of the engines has not been realised, in some cases these parts were varying and required significant changes to the blocks to enable the parts to be fitted! The time and costs involved in the supply assembly and testing of engines is quite considerable and it is often as costly to use old parts as the supply of new better designed parts which can afford much more reliability and longer engine life. We have therefore decided that we should focus our offering to the fully finished block, sumps and complementary parts for which our up rated crankshaft can be used using modern thin walled bearing shells. On this basis all new blocks are to this standard and will be available ex stock, we have a new crankshaft on the shelf for a PVT engine assembly so can offer a very predictable delivery.

Following this preamble we will itemise each major part we can supply and the reasoning behind the parts where significant improvements have been made, the fundamental behind all parts is as follows:-

To offer both Pre War and Post War Engine parts

Where essential major Castings have been strengthened.

Significant attention has been made to ensure increased and good oil flow, filtering and pressure control.

Water and Combustion Chamber Sealing has been improved with re-designed cylinder liners, sealing and modern design head gaskets.

The use of stronger/stiffer crankshaft designs has allowed the use of modern thin wall shell bearings which enables higher loads to be taken safely with higher RPM opportunity to gain higher power levels over a wider Rev range.

Parts have been made lighter where possible particularly the parts such as flywheels, starter motors and in particular Cylinder Heads by the use of Aluminium rather than Cast Iron.

We employ high quality specialist manufacturing companies to produce tooling, castings and carry out machining using the latest computer aided machinery, we use the highest grades of materials and latest processes in the manufacture of specialist parts. Assembly has been simplified so that minimal manual intervention is necessary to complete a satisfactory engine build, we have minimal use of gasket sealing as the machining quality is such that modern liquid sealants can be adopted.

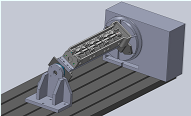

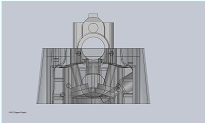

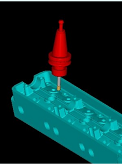

We will show some Computer Aided Manufacturing diagrams used in the manufacture of major parts this ensures compatibility of the parts to achieve accurate alignment which in particular applies to the relationship of the crankshaft to the cross shaft gears to ensure proper gear meshing which is critical for the engine performance and life.

Old News